im3rd-media-HlJuQDBh3w4-unsplash

im3rd-media-HlJuQDBh3w4-unsplash

im3rd-media-HlJuQDBh3w4-unsplash

im3rd-media-HlJuQDBh3w4-unsplash

im3rd-media-HlJuQDBh3w4-unsplash

im3rd-media-HlJuQDBh3w4-unsplash

im3rd-media-HlJuQDBh3w4-unsplash

WHAT CAN WE BUILD FOR YOU?

We pride ourselves on quality, commitment, and a seamless process for our customers.

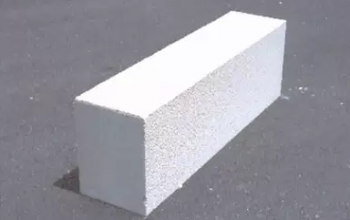

ScotBuild is a leading Autoclaved Aerated Concrete (AAC) Provider / Installer

NATURAL INSULATED

Keeps summers cool, winters warm and electricity bills low.

FIRE RESISTANT

Virtually fireproof for worry free hot seasons.

ECO-FRIENDLY

Made 100% sustainably out of natural components.

PEST PROOF

Impenetrable to common pests like termites.

Why AAC for Eco Friendly Building?

Autoclaved Aerated Concrete (AAC) is well known as an environmentally friendly construction material. The energy consumed in the production process is only a fraction compared to the production of other materials. The manufacturing process emits no pollutants and creates no by-products or toxic waste products.

An AAC Block is manufactured from common and abundant natural raw materials. The finished product is twice the volume of the raw materials used, making it extremely resource-efficient and environmentally friendly.

Build AAC anywhere in the USA:

You can get AAC material from anywhere in USA just contact us and one of our Representative will help you out with all the information you required.

AAC Tools and Fasteners:

Get in touch with us, we can share all the information and tools required to construct Eco Friendly AAC housing and structures.

Get Training from us:

We can help you out how you can utilize AAC materials with our top notch industry professionals who can train you with the extensive experience and best industry practice.

AAC since 1920:

Lot of us are not aware that AAC was perfected in the mid-1920s by the Swedish architect and inventor Dr. Johan Axel Eriksson, The process was patented in 1924. In 1929, production started in Sweden at the city of Lilla Yxhult

Why AAC is Better Than other Material:

Being light weight AAC drastically reduces the dead weight of the building, resulting in to the reduction in steel (up to 27%) and cement (up to 20%) structural cost savings. Being 8 times the size of clay brick, AAC wall construction involves 1/3rd the joints, thus an overall mortar saving up to 66%.

OUR PROCESS

From receiving your quote, to the planning process, to completion.

GET QUOTE

Contact us to setup an appointment for a free consultation and estimate.

SERVICE AREA

From Scotland & Building AAC all over the United States of America

ABOUT US

We are a family-based business from Scotland with over 30 years of combined experience.