Benefits of AAC

Eco-friendly

A AAC home is a quiet one because it reduces noise transmission. Compared to other building materials the use of AAC for external walls reduces noise from external sources like traffic, meaning more peace and quiet. And when used for upper floors, AAC can reduce sound transference between levels as well.

Quality and Speed

Since AAC removes the need for wood framing, insulation, sheathing, and dry wall. The process of building a house is dramatically reduced in time and cost. AAC is far more energy efficient and does not off gas so its quality is far superior to its other building material counterparts.

Energy Efficient

If you’ve felt your blood pressure go through the roof after opening an electricity bill recently, you’re among the millions of Americans who are experiencing the negative impact of increased energy prices.

However, the silver lining to this issue is that people are now doing more research into building products that can reduce their reliance on cooling and heating. This has seen homeowners choose products, like AAC panels, that have excellent insulation properties, allowing them to feel comfortable year round without it costing a small fortune.

Fire Resistant

AAC can stand up against most natural disasters if built correctly; most specifically, it is very fire-resistant. It has one of the highest hourly fire resistance ratings per inch of any building material out there. Just a 4-inch AAC wall carries a 4-hour UL rating. AAC is also non-combustible and does not emit dangerous chemicals when in direct contact with a heat source. Additionally, with an AAC wall, it has 1-3 components vs a typical wood frame wall with 7-13

Other Benefits of AAC

Mold Proof – Unlike other building materials AAC is natrually resistant to Mold.

Durability – Experience enduring strength with Autoclaved Aerated Concrete blocks. Superior to ordinary blocks, AAC is made of non-biodegradable materials and resistant to mold. Its remarkable strength also provides added stability to your construction.

Pest Proof – AAC is termite and other bug proof. Also AAC is also very resistant to rodents and other animals as well.

Doesn’t Emit Any Toxins – AAC is made from very common materials. Normally sounced from the surrounding area of manufacture. It doesn’t have hazordous chemicals or plastics that will off-gas in your home.

Faster Construction – Accelerate your construction with Autoclaved Aerated Concrete blocks. Their larger size and reduced number of joints make them easier to handle, resulting in quicker completion times. With the added advantage of being easily cut to the desired size and shape, AAC blocks simplify the building process.

AAC vs Other Materials

So, what are the advantages of Autoclaved Aerated Concrete (AAC)?

Lightweight (80% lighter than concrete- it will even float on water!)

Strong against extreme weather conditions. Structure can be engineered according to weather concerns of the area Earthquakes, hurricanes, flooding, wildfire, etc.

- Non-combustible * UL fire rating of 4 hours for a 4-inch non-load bearing wall * Does not expel toxic gases when exposed to fire * Ideal for wild-fire prone areas

Energy efficient in hot and cold climates * AAC cellular structure creates unique thermal properties resulting in a “mass enhanced R-Value.” * Combining high heat loss resistance with thermal inertia * Great for large day to night temperature swings * Monthly savings on heating and cooling cost

Impervious to pests, termites and other wood boring insects.

- Mold-proof and vapor permeable walls * As an inert mineral product, AAC will not succumb mold and decay.

- Reduced sound transmission * AAC has a high STC rating (Sound Transmission Class) due to the porous structure of the material it performs as an acoustic insulator, therefore reducing sound transmission.

- Eco-friendly materials and building process * Manufacturing AAC materials does not emit any pollutants into the environment and uses a minimal amount of energy and natural resources to produce.

- Flexibility with remodeling and decorating * Interior walls can easily be moved and reassembled for simple remodeling. * AAC can be cut, drilled, shaped and sanded easily with hand or power tools. * Electric chases are easily sawn or routed in.

* Screws and nails can be used just as a wood build house. - Legacy Value– the home will easily outlast the life of a wood-frame home while requiring less maintenance. Reducing the overall long-term expense of a home.

- Design options * AAC exteriors can be designed with the aesthetic of your choice. It can be fitted with stone, cement board siding, brick, metal & wood siding, etc. * Interior walls can be sanded down, and no additional materials are needed for a finished product. * However, interiors can be direct plastered with a base coat, followed by stucto-lite plaster or drywall compound if desired.

- Eliminates the need for sheetrock.

There are countless other advantages to using AAC not listed above. Over 60% of new home construction in most central European countries are currently built using Autoclaved Aerated Concrete. The build process is fast and efficient with a contractor trained on using the material.

Currently a wood-framed home in the US is 4-10% less expensive to build up front, but the long-term cost of owning a wood-frame home can easily offset that cost within just a few years.

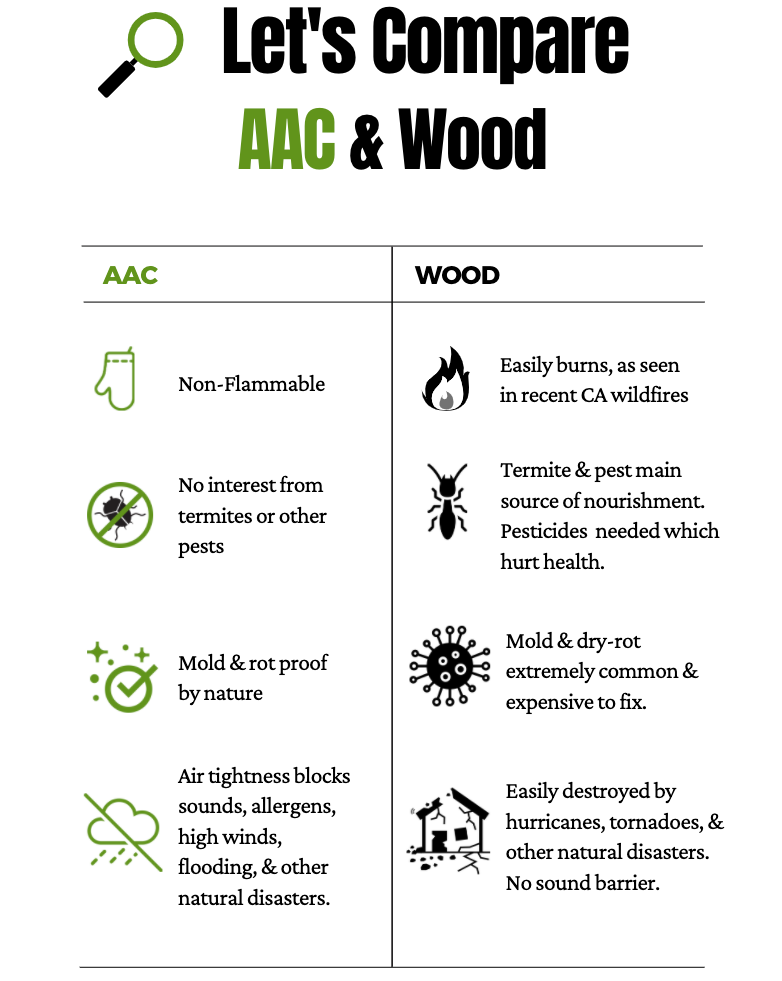

How different is this material from traditional wood homes build in the USA? Below is a breakdown of just a few key issues and expenses you will find in a wood framed home:

Wood burns easily and cannot withstand a wildfire.

Easily destroyed in an earthquake o If survives seismic activity, the home is still in danger of fires resulting from gas line damage (Kobi Earthquake, Japan 1995).

- Termite damage.

- Mold and dry-rot * Especially relevant in areas with regular snow and rain.

- High wind and hurricane damage can completely destroy or cause significant damage.

- Flooding treatment is much more extensive and expensive than with AAC * Remove sheetrock to dry-out the frame and treat wood against mold before rebuilding (AAC would only require pressure washing.)

- Extra cost for sound-proofing.

- Need for insulation products which have been found to be toxic over time.

- Higher annual energy costs due to poor insulation products.

- Susceptible to structural damage and requires more longterm maintenance than AAC.

- Certain treated wood products used in homes are toxic and no longer permitted in parts of Europe.