What Is AAC

Autoclaved Aerated Concrete is a strong, versatile, high performance building product. It was developed over 85 years ago by Swedish architect Johan Axel Ericksson. It is now being produced in more than 300+ factories around the world.

We have over 30 years of experience with the material, meaning you can be assured you are getting a high quality product installation with the technical expertise to back it up.

The material is available in blocks and panels. AAC is easy to handle, quick to build with, and better to live in. AAC panels contain anti-corrosion steel reinforcement for added strength and are available in a range of lengths for applications including walls, floors and external cladding.

Concrete (AAC) shell structures ( Kits ) for homes and commercial buildings. AAC shells remove the need for wood framing, insulation, sheathing, and drywall. Not only is the build extremely fast in comparison to wood-framed homes, but they can save up to 35% in energy costs and over 25% in insurance costs.

Additionally, the need for maintenance is drastically less throughout the lifetime of the home. AAC can stand up against most natural disasters if built correctly, most specifically it is very fire resistant. It has one of the highest hourly fire resistance ratings per inch of any building material out there. Just a 4 inch AAC wall carries a 4-hour UL rating.

AAC is also non-combustible and does not emit dangerous chemicals when in direct contact with a heat source. Additionally, with an AAC wall, it has 1-3 components vs a typical wood frame wall with 7-13. With the rising cost of lumber throughout the United States, the cost of building with AAC is very competitive with the current market. AAC is fire-resistant, energy-efficient, impervious to pests, and requires fewer materials to complete the build.

While some builders here may have heard of AAC, the correct technique and proper tools are not commonly found in the US. However, I have availability to all of the tools and fasteners needed to comply with all the code requirements in the US. This includes my access to the material, which I can ship anywhere in the USA & Canada While AAC is not very well known in the United States, it has widely been used all around the world since 1924. I am here to help establish it in the US to help build efficient and eco-friendly homes & commercial buildings.

I am very passionate about the benefits of using AAC and am excited to bring my knowledge of the product to others.

Making AAC

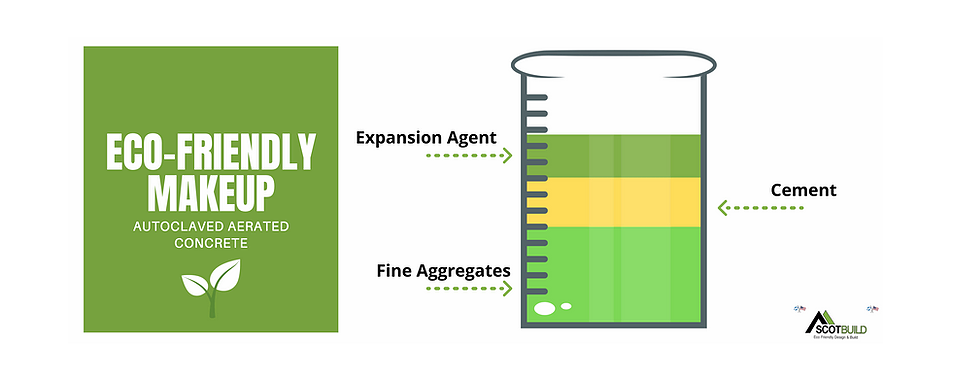

AAC is made from fine ground silica sand, Portland cement, lime, water and aluminum powder as an expansion agent. The production process is very carefully monitored to insure a controlled consistency in the proportions and timing of all ingredients that are used in each batch.

The materials are first mixed into a slurry and then poured into large molds where the expansion agent reacts with the alkalis in the cement and lime to produce millions of small hydrogen gas bubbles.

The mix expands and rises almost 2 times its initial volume. The hydrogen evaporates and the ‘cake’ sets up and hardens into a stable closed cell matrix which can then be precision wire-cut into blocks or panels.

The green aerated concrete is then steam cured in a pressurized autoclave for about 12-14 hours where upon it undergoes a second chemical reaction and transforms into the mineral Tobermorite or calcium silicate hydrate. The finished materials are palletized, wrapped and delivered by truck to the job site.